TCS Resins

Top Features of TCS Resins

-

1

Lightweight & comfortable.

-

2

Aesthetic. Manufactured to blend naturally making it undetectable in the mouth.

-

3

Long lasting & durable.

Superior quality materials. -

4

BPA & Monomer Free.

-

5

Stain resistant.

Technical Worksheets

Catalog

Finishing and Polishing eBook

Times and Temperatures

EZ Flow

Injecting with FRS

Fabricating TCS Flexible Partials

Rebase

Repair

Suction Cup

Technical Library

Unbreakable

Nylon thermoplastic with unbeatable strength-

Extremely resilient, high performing nylon thermoplastic for flexible partial.

-

Ideal for flexible partials.

-

Guaranteed unbreakable due to its unique properties.

-

Designed for exceptional memory to hold its form.

-

Offers an ideal degree of flexibility.

-

Repairable.

-

A modern fit, lightweight and durable.

iFlex™

Polyolefin thermoplastic with translucent finish-

Highly translucent, polyolefin thermoplastic for flexible partials.

-

Ideal for flexible partials.

-

Simple to finish and polish.

-

Stain resistant and easy to maintain.

-

Offers an ideal degree of flexibility.

-

Repairable.

-

A modern fit, lightweight and durable.

Karadent™

An upgrade from acrylic without compromising stability-

Semi-rigid, microcrystalline polymer thermoplastic.

-

Ideal for full dentures, semi-flexible partial dentures, clear clasps, frameworks, and nightgurads.

-

No volume shrinkage for exceptional fit.

-

An upgrade from traditional acrylic but as simple to finish and polish.

-

Stain resistant and easy to maintain.

-

Easy to repair and rebase (lab procedure).

-

A modern fit, lightweight and durable.

Insurance Codes

D5225 Maxillary, D5526 Mandibular

Unbreakable™ and iFlex™ are available in:

Shade 1 – Light Pink

Shade 2 – St. Pink

Shade 3 – Lt./Dk. Pink

Shade 4: Dark Pink

Shade 5: Natural (white-ish)

Karadent™ is available in:

Shade 2 – St. Pink

Shade 4: Dark Pink

Shade 5: Natural (clear)

Millable discs available in limited shades. Click below to view:

Indications for Unbreakable™ and iFlex™:

- Economical, aesthetic solution for missing teeth

- Patients with concerns over metal restorations

- Gingival veneers to mask exposed root surfaces

- Patients with allergies to monomer and/or nickel

- Transitional restoration during the healing period for implants

- Patients with the presence of tori

Indications for metal with Unbreakable™ and/or iFlex™

- Need for more rigid appliance due to poor tissue support or few remaining teeth

- Free-end saddle with teeth missing from the 1st bicuspid

- Cast rest seats if soft tissue is a concern

Note: Consider Karadent™ when more stability is required.

Indications for Karadent™

- Full dentures, partial dentures, clear frameworks, and nightguards

- Economical, aesthetic solution for missing teeth

- Patients with concerns over metal restorations

- Patients with allergies to monomer and/or nickel

- Transitional restoration during the healing period for implants

- Partial dentures when more stability is needed due to poor tissue support or few remaining teeth

- Partial dentures when more stability is needed for free-end saddles with teeth missing from the 1st bicuspid

Contraindications for Unbreakable™ and iFlex™:

- Full dentures

- Immediate application: due to recession, allow 8 to 10 weeks healing time when prescribing a TCS restoration as a permanent solution

Contraindications for Karadent™:

- Flexible partial dentures

- Patients with the presence of lingual tori

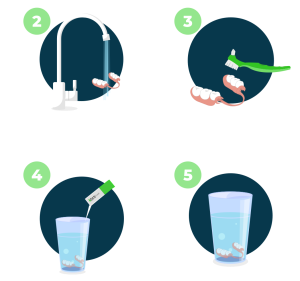

TCS appliances are very easy to care. The American Dental Association (ADA) and the American College of Prosthodontists (ACP) recommend that dentures be cleaned daily by soaking and gently brushing with an effective, non-abrasive denture cleanser.

We recommend using TCS Fresh Dental Appliance Cleaner. Click to learn more.

An Acrylic Upgrade

Karadent™’s unique formula achieves the unbreakable strength of nylons with the simplicity of acrylics to create the most stable and durable removable appliances the industry has been waiting for.

It’s Clear shade allows for designs with complete transparency. Ideal for frameworks, clasps, and nightguards.

Flexibility and Translucency

TCS resins vary in flexibility and translucency. The flexibility and translucency will depend on thickness and design of each TCS appliance. The chart to the left gives a general idea on the variations of each resin.

If you are unsure which resin is best for a particular case, please contact us at:

info@tcsdentalinc.com | (866) 426-2970.

Finish and Polish

Finishing and polishing TCS resins is easy with our tools and guided assistance. We are always here to help you master or simplify your finishing and polishing process.

- Finishing and Polishing eBook

- Tech Support

- Online Training

FAQ's

TCS offers three distinct resins to fabricate removable dental appliances for patients with missing teeth. The characteristics of TCS resins allow lab technicians to create thin and comfortable appliances. Unbreakable™ is a nylon thermoplastic material popularized for its unbeatable strength and excellent elastic memory. iFlex™ is a polyolefin thermoplastic material famous for its stain-resistant properties, and its simplicity to finish and polish. Karadent™ is a semi-rigid microcrystalline polymer praised for its strength, stability, and no volume shrinkage. Karadent™ is an upgrade from acrylic dentures that is ideal for full dentures, clear clasps, and frameworks. Meanwhile, Unbreakable™ and iFlex™ are ideal for flexible partial dentures. All TCS resins are capable of easily fabricating BPA and monomer free removable dental appliances that are aesthetic and durable for everyday use.

Although all three TCS resins are formulated with aesthetic, functionality, and patient comfort in mind, choosing the right material for a particular case comes down preference and indication.

Between iFlex™ and Unbreakable™, both offer the same characteristics and functionality for flexible partial dentures. However, iFlex™ offers higher translucency in comparison to Unbreakable ™.

Unlike iFlex™ and Unbreakable™, Karadent™ is ideal when a full denture, clear framework, or nightguard is prescribed. Additionally, Karadent™ is excellent for partial dentures that require a rigid material, and for large cases where flexibility in the pallet area is not recommended.

All resins are BPA free and monomer free. For thorough indications and contraindications for each resin please visit Unbreakable™, iFlex™ or Karadent™.

All three of our resins are meant to last a lifetime. Although some of our resins are considered unbreakable, the longevity of an appliance will depend on how well the patient cares for their appliance. We recommend the TCS Concentrated Dental Appliance Cleaner to keep appliances looking and feeling like new.

TCS resins are high-quality thermoplastics that come in a variety of cartridge types and sizes with various shades. Prices will vary depending on the cartridge type and size. Furthermore, because TCS does not sell direct, prices will vary depending on the distributor you purchase from. For pricing on TCS resins please contact your distributor or one of our Authorized Distributors.

Unbreakable™ and iFlex™ are available in 5 shades: Light Pink, Standard Pink, Light/Dark Pink, Dark Pink, and *Natural. * The TCS Natural shade is a filmy white shade that is virtually invisible when used for a clasp near the abutment tooth.

Karadent™ is available in 3 shades: Standard Pink, Dark Pink, and Clear.

We offer free shades guides to use as a reference when matching a patient’s natural gingiva to a shade. Contact us to get your shade guide today.

Out of all the TCS resins, iFlex™ is considered the most flexible. However, depending on the thickness of an appliance, all TCS resins are capable of flexibility. Even Karadent™ may become slightly more flexible with thinness.

iFlex™ offers a slightly higher translucency than Unbreakable™ and Karadent™ finishes completely transparent in shade Clear.

Unbreakable™:

When using the TCS Manual Injector or the TCS Hydraulic Injector in conjunction with the TCS Digital Furnace or with any injector:

- Using 25mm cartridges

- 550°F (288°C) | 11 min

When using the TCS Automatic Air Injector 110V:

- Using 25mm cartridges

- 320°C | 11 min | 145 – 150 PSI

iFlex™:

When using the TCS Manual Injector or the TCS Hydraulic Injector in conjunction with the TCS Digital Furnace or with any injector:

- Using 25mm cartridges

- 450°F (232°C) | 13 min

When using the TCS Automatic Air Injector 110V:

- Using 25mm cartridges

- 280°C | 13 min | 145 – 150 PSI

Karadent™:

When using the TCS Manual Injector or the TCS Hydraulic Injector in conjunction with the TCS Digital Furnace or with any injector:

- Using 25mm cartridges

- 550°F (288°C) | 15-16 min

When using the TCS Automatic Air Injector 110V:

- Using 25mm cartridges

- 320°C | 15-16 min | 150 – 165 PSI

All TCS resins are simple to work with. When it comes to finishing and polishing appliances made with iFlex™ and Unbreakable™, divide the partial into three sections and spend an equal amount of time in each section. Refrain from moving the partial in different directions, unlike acrylic dentures iFlex™ and Unbreakable™ should not be polished all at once.

Technicians have found that iFlex™ is easier to finish due to its softness. Polyolefin based materials (such as iFlex™) grind easier with less pressure in comparison to nylon-based materials (such as Unbreakable™).

Karadent™ is very easy to finish and polish because unlike acrylic, it requires less time to complete.

Unbreakable™:

For best results we recommend using the TCS Pink Zirconia Burs to finish and the Green Hi-Shine polishing paste to polish Unbreakable™.

Always apply Brown Tripoli with a clean Rag Buff on medium-high pressure before using Green Hi-Shine. Then apply the Green Hi-Shine using a dry Rag Buff at high speed with moderate pressure.

iFlex™:

For best results, we recommend using the TCS Pink Zirconia Burs to finish and the iShine polishing paste to polish iFlex™.

Always apply Brown Tripoli with a clean Rag Buff on medium-high pressure before using iShine. Then apply the iShine using a dry Rag Buff at medium-high speed with very light pressure.

Karadent™:

For best results we recommend using the TCS Pink Zirconia Burs or any acrylic burs to finish and the Green Hi-Shine polishing paste to polish Karadent™.

Always apply Brown Tripoli with a clean Rag Buff on medium-high pressure before using Green Hi-Shine. Then apply the Green Hi-Shine using a dry Rag Buff at high speed with moderate pressure.

For a step by step guide on finishing and polishing TCS resins, please view or download the Finishing and Polishing eBook.

Yes, a tooth may be added to any TCS appliance. All three TCS resins can be repaired in a laboratory procedure. However, a tooth can only be added using the same material as the original partial.

Unbreakable™ can be repaired with re-injection and a bonding agent, we recommend the TCS Fusing Liquid. View our step by step guide.

iFlex™ can be repaired with re-injection, no bonding agent (or fusing liquid) is needed but always overlap with existing material. Small repairs with the TCS Hot Air Welder are also doable yet, very difficult.

Karadent™ full dentures can be relined with acrylic. Other Karadent™ appliances can repaired with re-injection or a bonding agent (TCS Fusing liquid is recommended) with acrylic. Small repairs with the TCS Hot Air Welder are also doable yet, serve as a temporary ~6-month repair.

Please contact us for further details and assistance.

- Waxing too thick: Waxing too thick is the number 1 reason bubbles often occur. Flexible partials should be waxed approximately 1.5mm thick for small cases with abutment teeth and 2.5 – 3mm where the saddle connects to the abutment teeth in free end saddles. If a thicker wax-up is unavoidable, try to wax as close as possible to the final case.

- Incorrect spruing method: When spruing use 2 – 3 sprues at the tip end of a wax-up and be sure the connection between the sprue and the waxed model is thin. Adding too much wax to the connection may cause an air bubble. Avoid placing the sprues too close to the teeth, as this will also cause air bubbles underneath the teeth. Refer to the diagram below for proper placement and sprue thickness.

- Not using enough pressure: Use the correct pressure when injecting TCS resins. Injecting slowly or with a low pressure may cause bubbles to develop.

- Overheating the flask: If injecting Unbreakable™ or iFlex™, the flask should be at room temperature. (When working with a TCS Automatic Air Injector Unit, DO NOT leave the flask in the injecting position during the entire melt time. Alternatively, position the flask on top of the machine 1 minute before injecting).

- Using the wrong cartridge size: Select the right cartridge size on a case by case basis. If a case is larger than the selected cartridge, the material will not fill the case properly, causing bubbles to cover the partial.

The TCS Hot Air Welder can serve as an easy fix for minor air bubbles. Click here to view a Step By Step Guide.

- Consistency: For a consistent bite reference when waxing, articulate both the duplicate model and the master model to mirror each other. Additionally, practicing the design on the model will result in aconsistent reference point.

- Overestimating: When preparing the model for investing, trim less of the wax-up than desired. It is best practice to have extra finishing room instead of risking a lack of coverage around the edges.

- Flask condition: Double-check the condition of your flask before injecting. Your flask should touch metal to metal, and the screw inserts must be stable.

- Lightly add separator or Vaseline: Avoid adding excessive amounts of separator or Vaseline. DO NOT apply separator or Vaseline in-between the metal halves as this may tamper the metal to metal contact of the flask.

- Use a buff stone: Avoid using anything other than a buff stone for investing. Mixing plaster with buff stone or using a material softer than buff stone is not recommended. Keep in mind that using a material harder than buff stone will make the de-flasking process more difficult.

- Using the TCS Putty correctly: Once a wax-up is invested, apply a thin coating of the TCS Putty around the replacement teeth. Make sure the cusp and incisor edges of the teeth are slightly visible. Before the putty hardens add retentive undercuts on the facial side of the putty.

Inadequate diatorics: One of the main reasons for tooth pop-outs is not having a distinct entrance and exit. Be sure to define the diatorics properly.

Separator not drying: If you use a separator that is not the TCS EZ Flow separator, be sure to apply thin layers and allow each layer dry completely. Additionally, avoid creating build-up around the teeth.

Inaccurate injection: Premature injection or injecting at low pressures prevents the material from properly flowing through the diatoric holes.

Incorrect boil-out: Improper boil-outs leave behind remnants of wax inside the diatoric holes and block the flow of the material when injecting.

Blocked flow: Setting the teeth too close to each other prevents the material from flowing through the diatorics and securing the teeth to the partial.

- Tiny Teeth: Using small teeth may result in a pop out due to not having enough stability. It is best practice to avoid using tiny teeth.