-

1

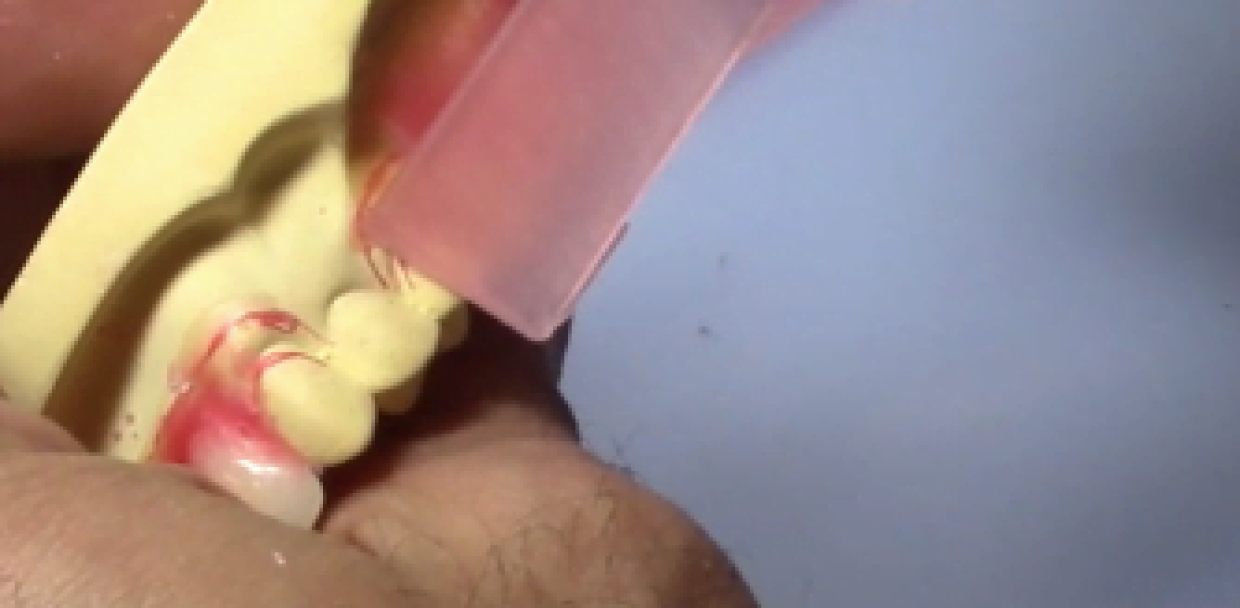

Waxing to an ideal thickness.

Wax to the ideal thickness the case requires, not thinner, not thicker. Remember, the thicker the wax up the higher the chances air bubbles will form. Use TCS wax patterns to help achieve proper wax thickness.

-

2

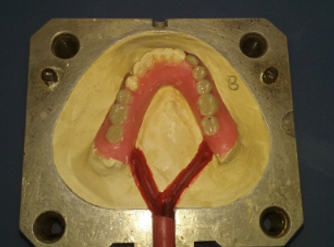

Placement of the sprues.

Avoid placing the sprues too close to the teeth when possible. Sometimes this causes air bubbles to appear underneath the teeth. Instead, place sprues at the tip end of the wax up.

-

3

Choosing the correct size tooth when setting up.

Choosing shorter teeth and leaving a large space of thick wax up under the teeth is another reason why bubbles occur. These bubbles usually appear underneath the teeth. Be sure to choose longer teeth to avoid this from happening.

-

4

Pay attention to heat and pressure.

Remember, different resins and injection units require different times, temperatures, and pressure. Follow the manufacturer's instructions.

-

5

Choose the right size cartridge for each case.

If a case requires a thicker wax-up using a large cartridge will help avoid bubbles from forming.

-

6

Avoid applying too much separator.

Applying too much separator, not allowing it to absorb, and/or using dense separators may prevent the material to flow correctly causing air bubbles and leaving unusual marks behind.